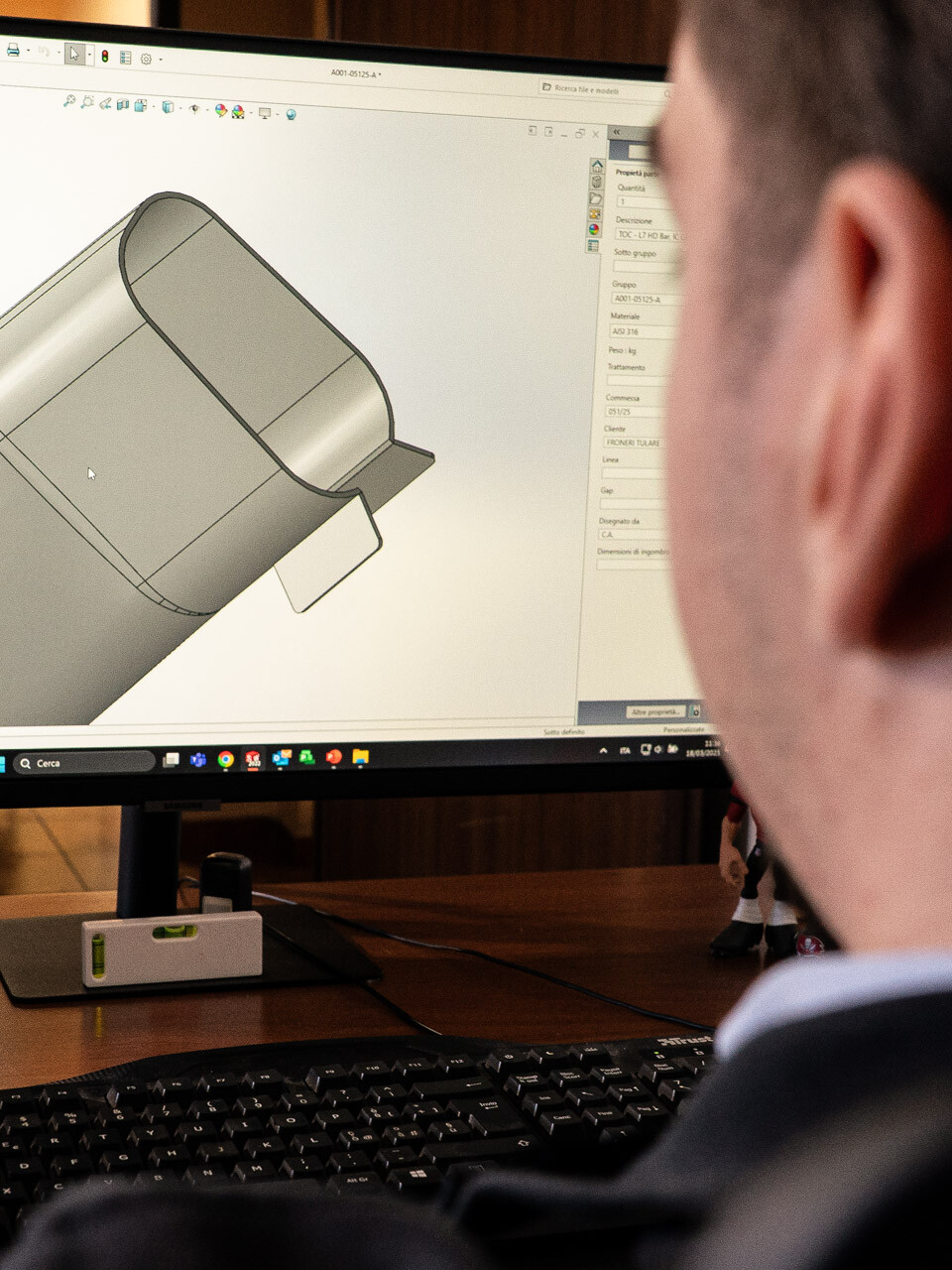

Revamping

Excellence in Industrial Revamping

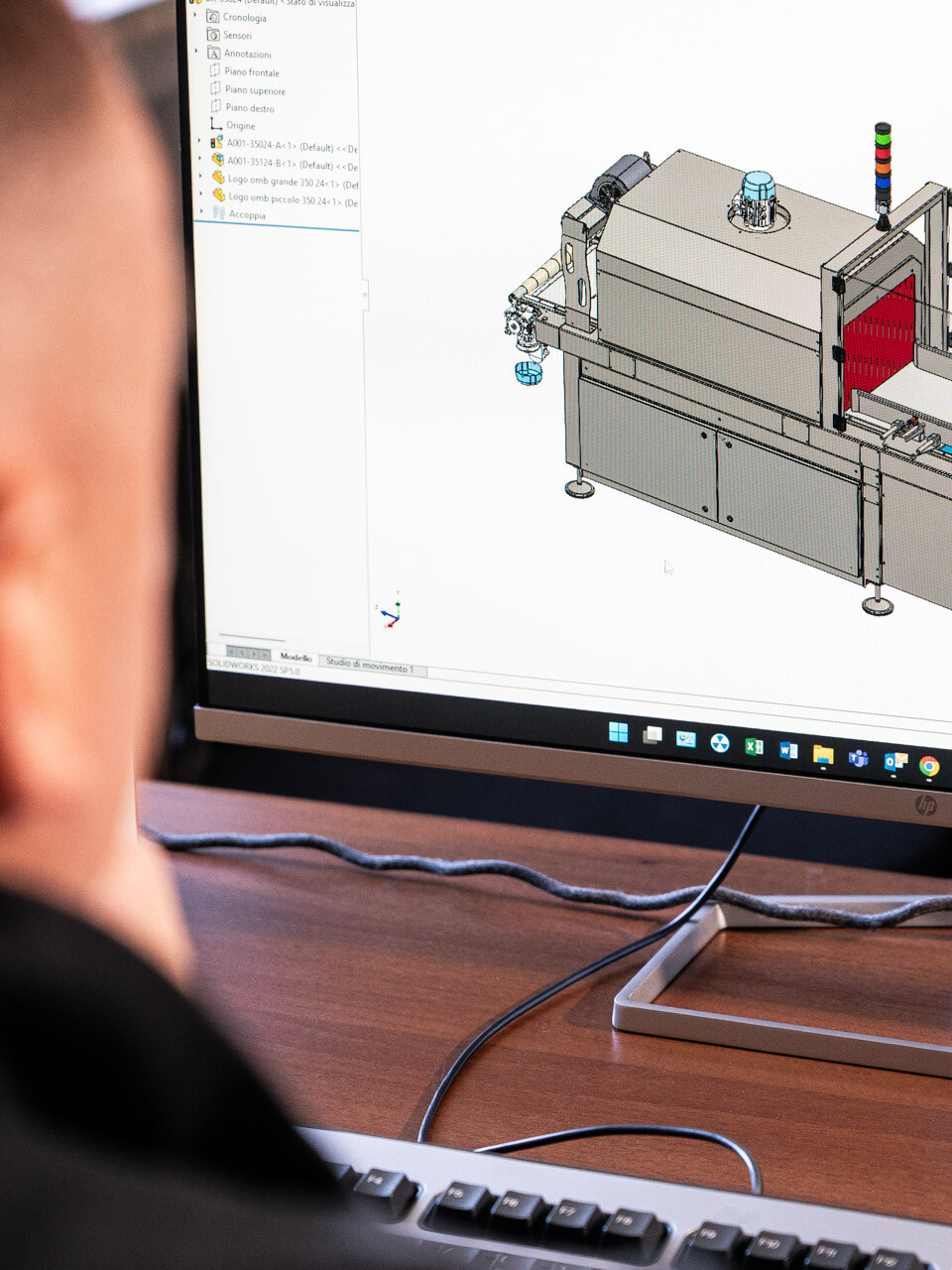

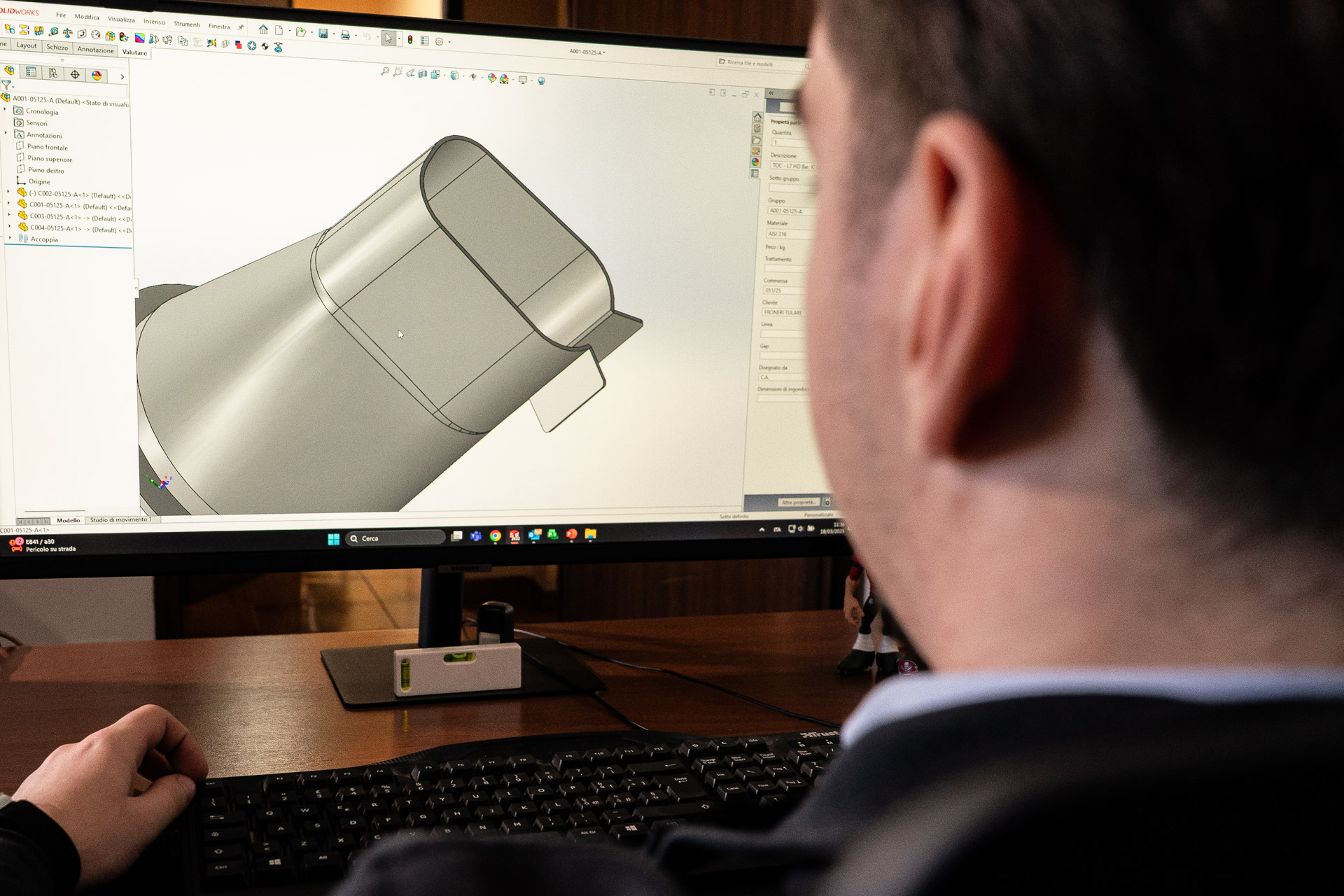

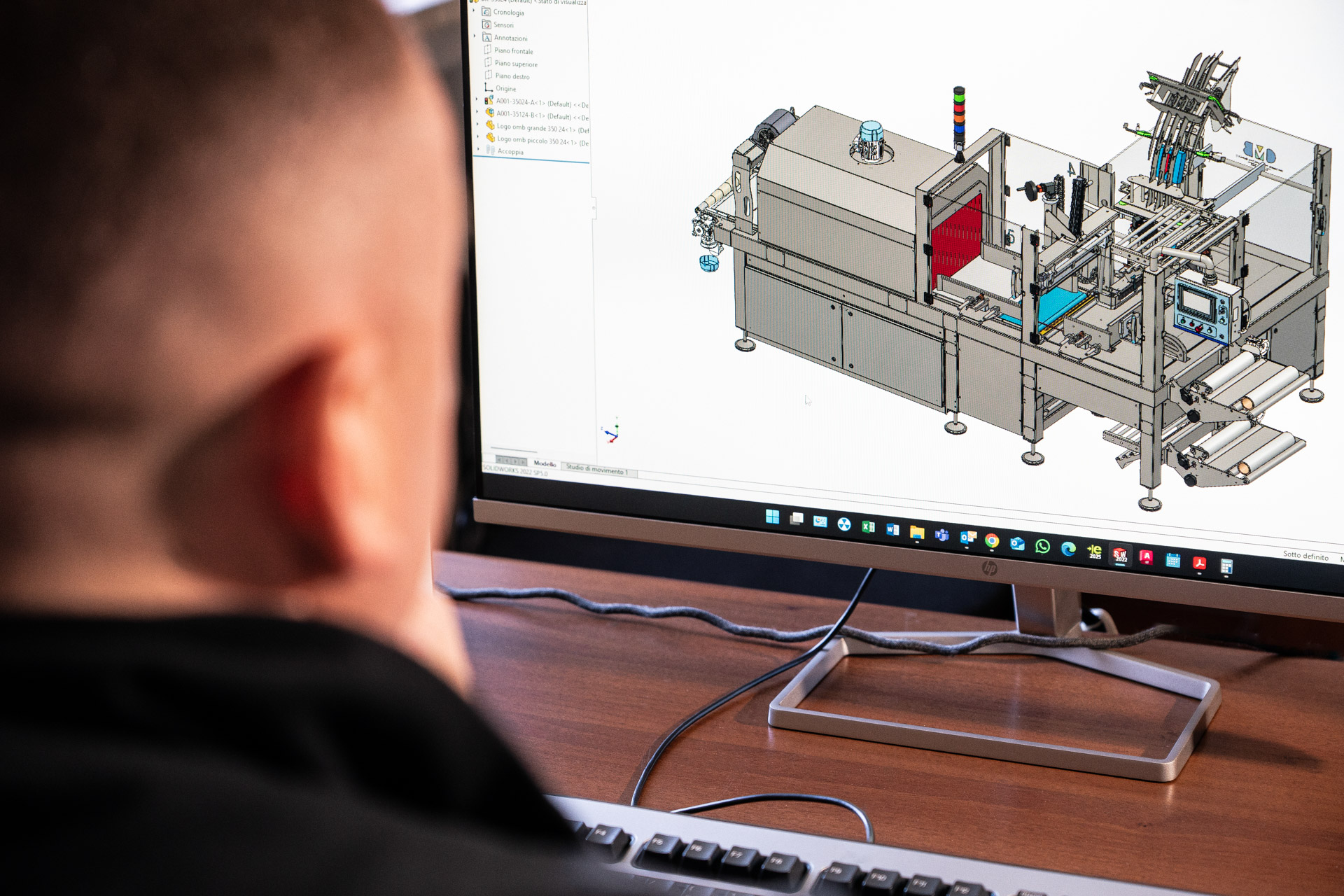

OMB stands out for its expertise in carrying out revamping operations, with a focus on the renovation and refurbishment, either total or partial, of industrial plants. This solution represents a highly effective method for adapting production lines to new production and safety requirements, without the need for a complete replacement, which is often avoided due to cost or feasibility reasons.

There are many reasons to undertake a revamping intervention: from increased productivity to improved product quality, from compliance with safety regulations to the integration of advanced control systems and statistical production monitoring.

Through revamping, OMB allows for the renewal of the technological core of plants, optimizing them for current production needs and enhancing their competitiveness. This strategy allows for the enhancement of existing resources, while ensuring the necessary flexibility to tackle the challenges of an ever-evolving market.

Thanks to our solid experience, OMB is the ideal partner to guide companies through a process of modernization and targeted optimization of production lines, ensuring strategic and effective interventions.

Maintenance

Strategic Maintenance Management with OMB

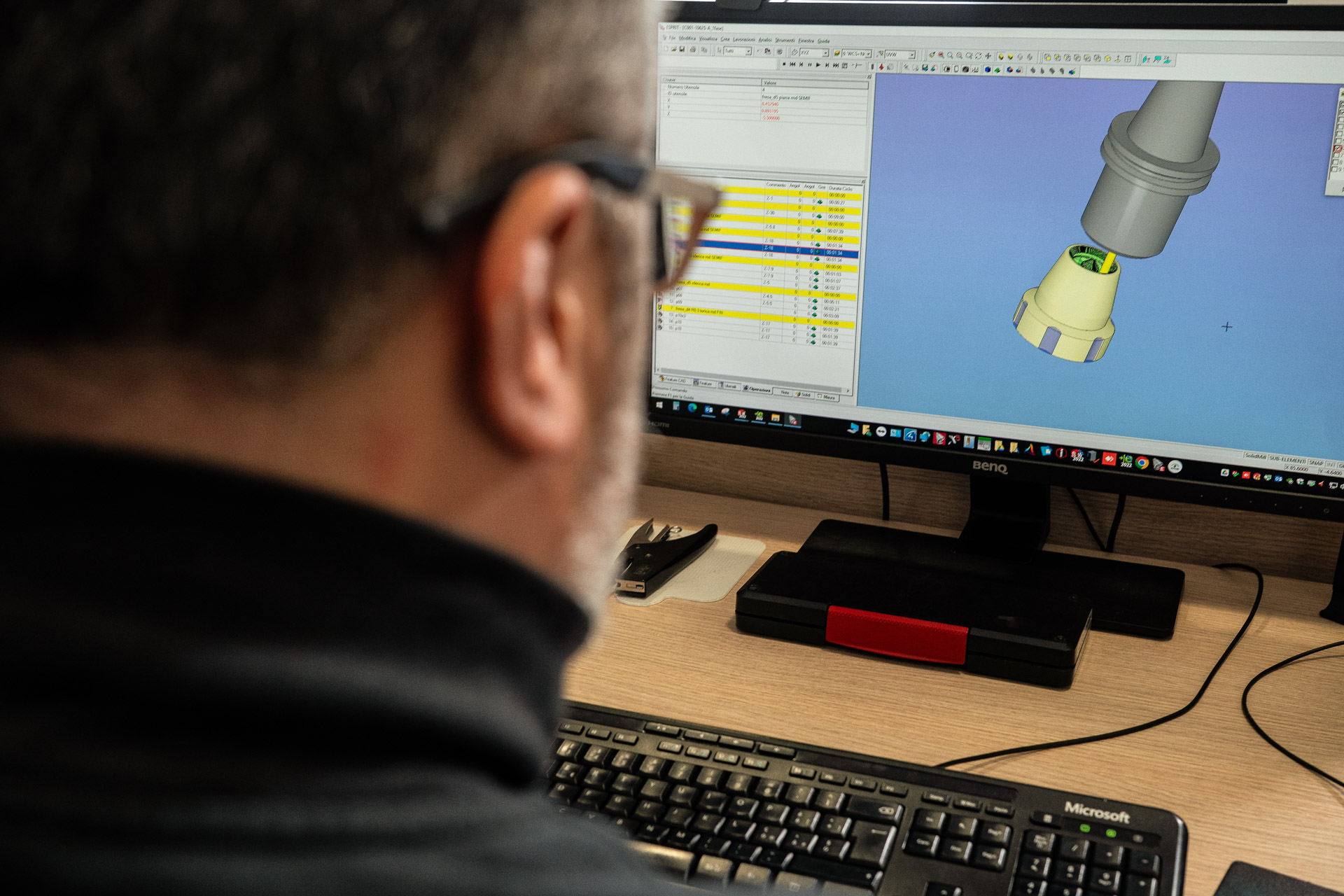

The choice of maintenance strategy depends on two fundamental aspects: on one hand, improving the reliability of machines through advanced technological solutions; on the other hand, optimizing operational costs by balancing maintenance investments with losses resulting from breakdowns.

In plant management, the importance of maintainability is growing increasingly, with a strong push towards preventive approaches aimed at minimizing the risk of malfunctions and machine downtime.

OMB stands out for its adoption of predictive maintenance methodologies, using cutting-edge monitoring tools to promptly detect anomalies and prevent failures before they compromise plant operations. This approach allows for increased production efficiency and reduced downtime.

At the same time, the company ensures quick and effective interventions in the event of a failure, adopting corrective maintenance procedures that guarantee the timely restoration of machinery and continuity of production.

Thanks to an effective combination of predictive, preventive, and corrective strategies, OMB positions itself as a key partner for companies looking to improve the reliability of their equipment, optimize management costs, and ensure high standards of safety and operational efficiency.

Spare Parts

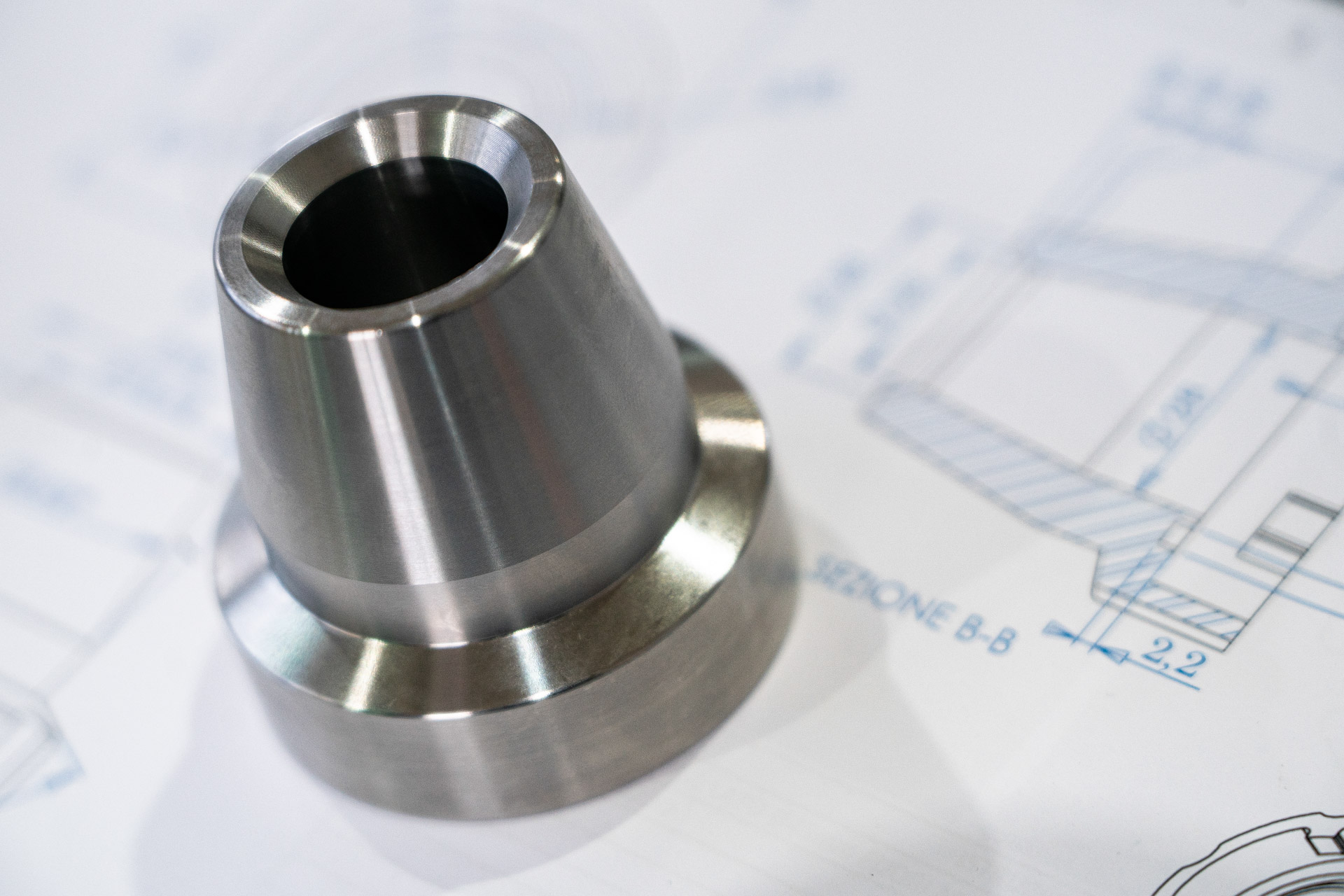

Spare Parts Management: A Structured System to Maximize Efficiency

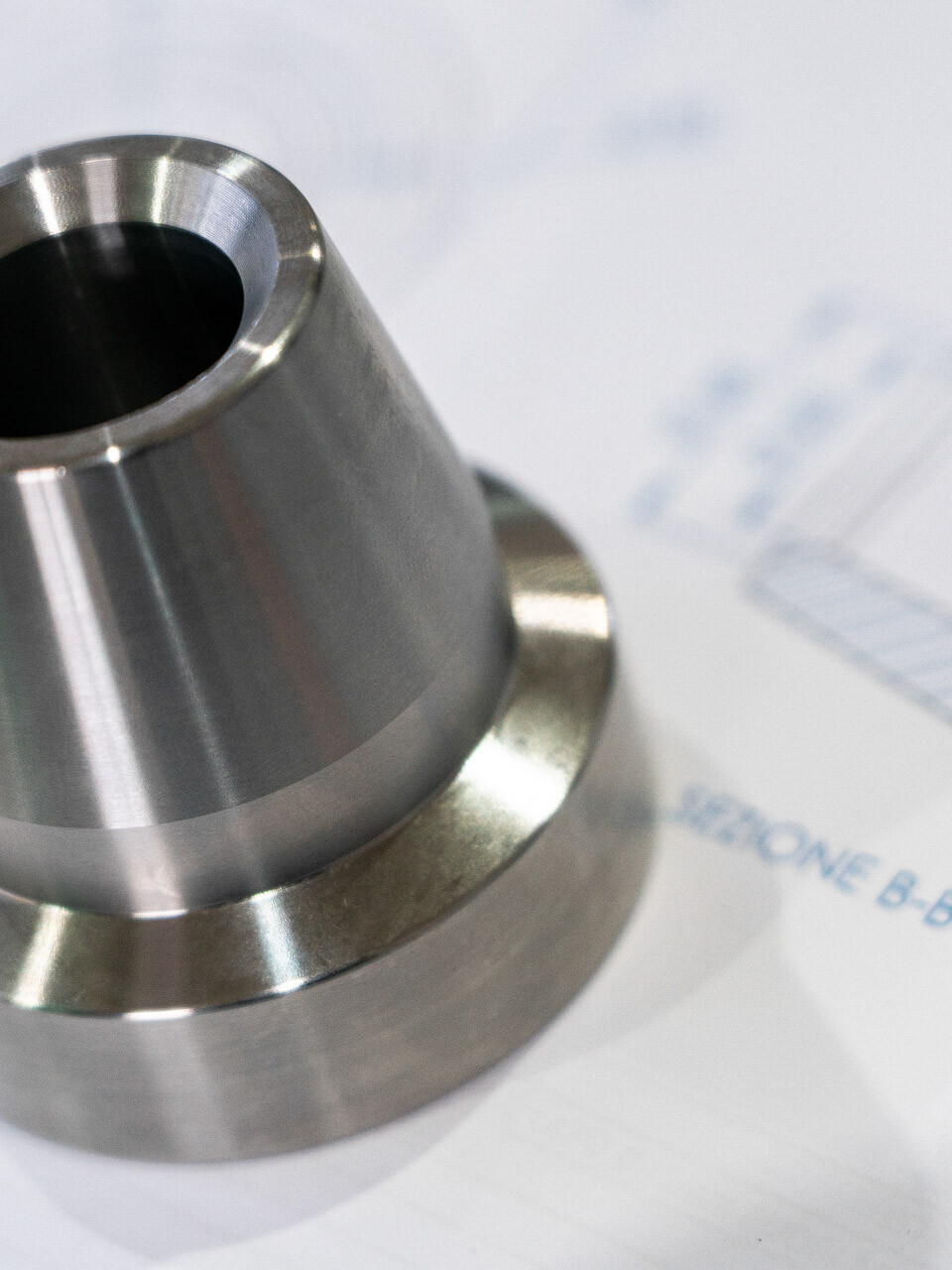

In the development phase of new machinery and plants, OMB immediately implements a detailed spare parts register, integrating it with the operational bill of materials. This database includes essential information, such as the unique identification code, component description, and stock availability, all easily accessible from your reserved area.

Thanks to this systematic organization, customers can quickly locate the necessary spare parts, minimizing waiting times and improving maintenance management. The clear and detailed structure of the archive allows for optimized technical interventions, preventing disruptions and ensuring timely support when needed.

This approach demonstrates OMB’s commitment to providing comprehensive support focused on ensuring the operational continuity of its clients. The precision in spare parts management is a strategic element to ensure reliable performance and minimize the impact of potential failures on productivity.

Change Format

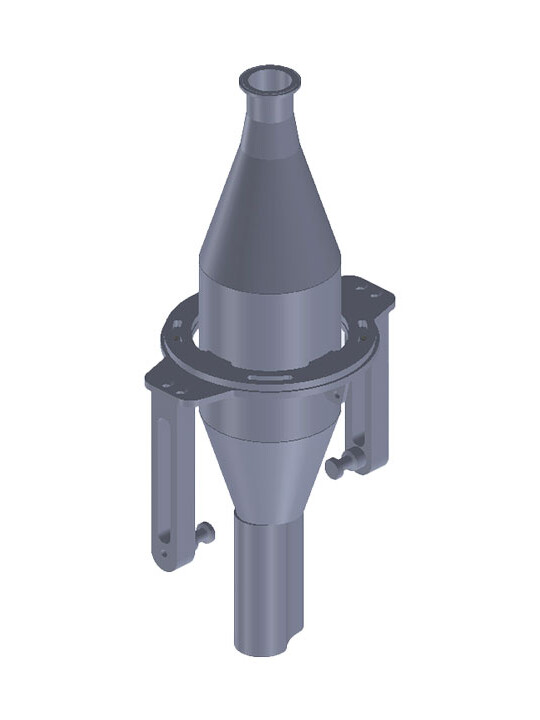

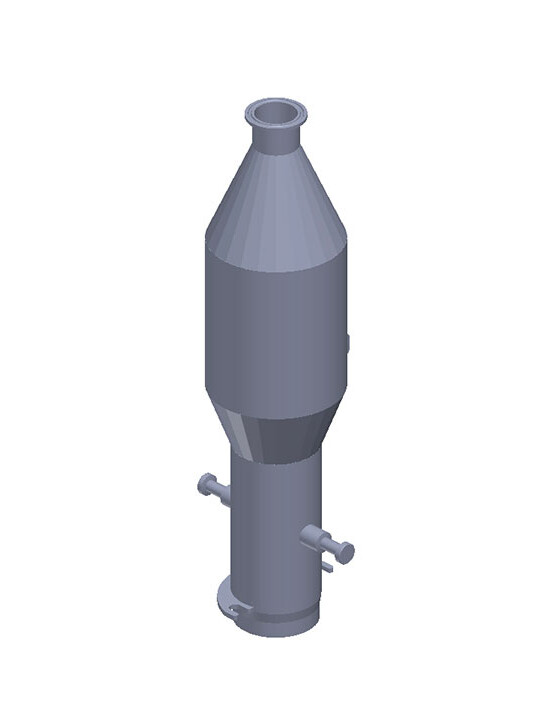

Optimization of Ice Cream Production Lines: Complete Format Change

The ice cream industry requires highly flexible production plants, capable of quickly adapting to new market demands and various product formats.

OMB supports its clients in carrying out complete format changes, intervening at every stage of the production line, from the worktable to the packaging of the finished product, ensuring operational continuity, precision, and maximum efficiency.

Thanks to a structured and customized approach, OMB ensures a quick and effective format change, reducing downtime and maximizing productivity.