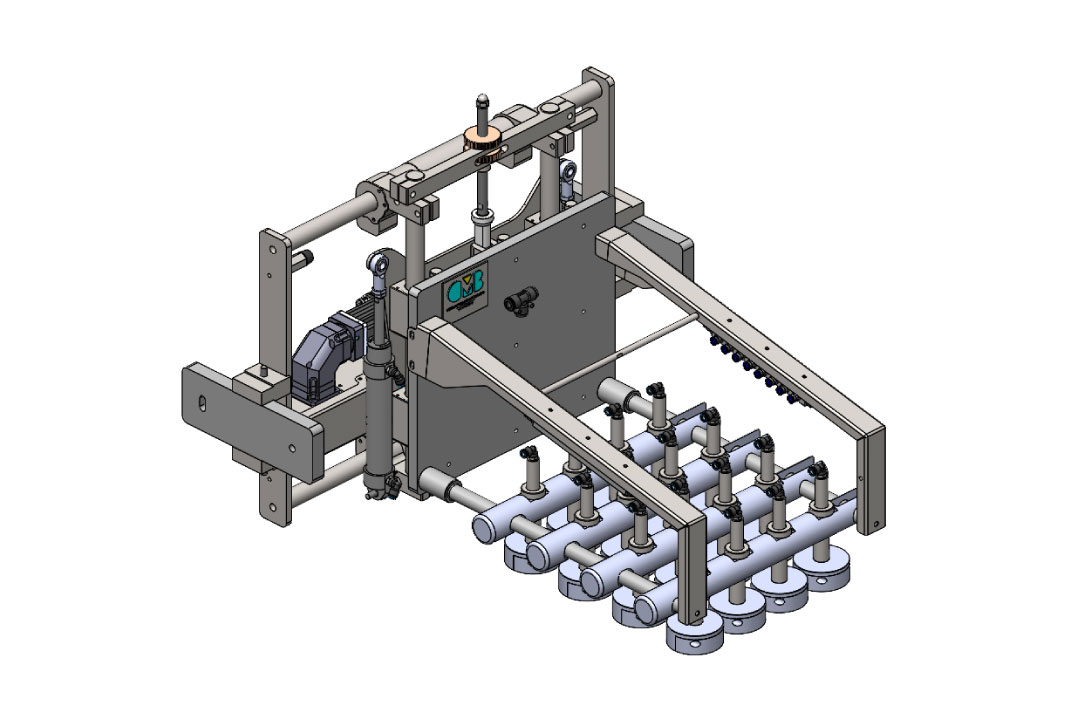

The Follow-up Press made of Sintered Material is designed to ensure uniform and controlled pressing of ice cream or other food products moving along the production line. Thanks to the tracking technology, the press adjusts to the speed of the line, ensuring precise application without compromising the product’s structure.

Made of high-strength sintered material, the press ensures superior anti-stick properties and reduced wear over time. The system is fully integrable with automated lines and controlled via PLC, allowing for precise adjustment of pressure and speed parameters according to production needs.

- Type: Follow-up pressing system for food products

- Compatibility: Suitable for ice cream production lines and other food products

- Efficiency: Dynamic and uniform pressing during the movement of the line

- Precision: Advanced pressure parameter control via PLC

- Reliability: Wear-resistant and anti-stick sintered material

- Interfacing: Compatible with industrial automation systems

- Hygiene and Safety: Made from certified materials for food contact, compliant with food safety standards.

- Structure: AISI 304 and Aluminum

- Parts in contact with the product: Sintered material

- Finish: Specific treatment for durability and ease of cleaning

- Custom configurations for different product sizes and geometries

- Integration Capability: Can be integrated with existing automation systems

- Control sensors to monitor pressure and tracking speed

- Installation and Training: Provided for the proper use of the equipment