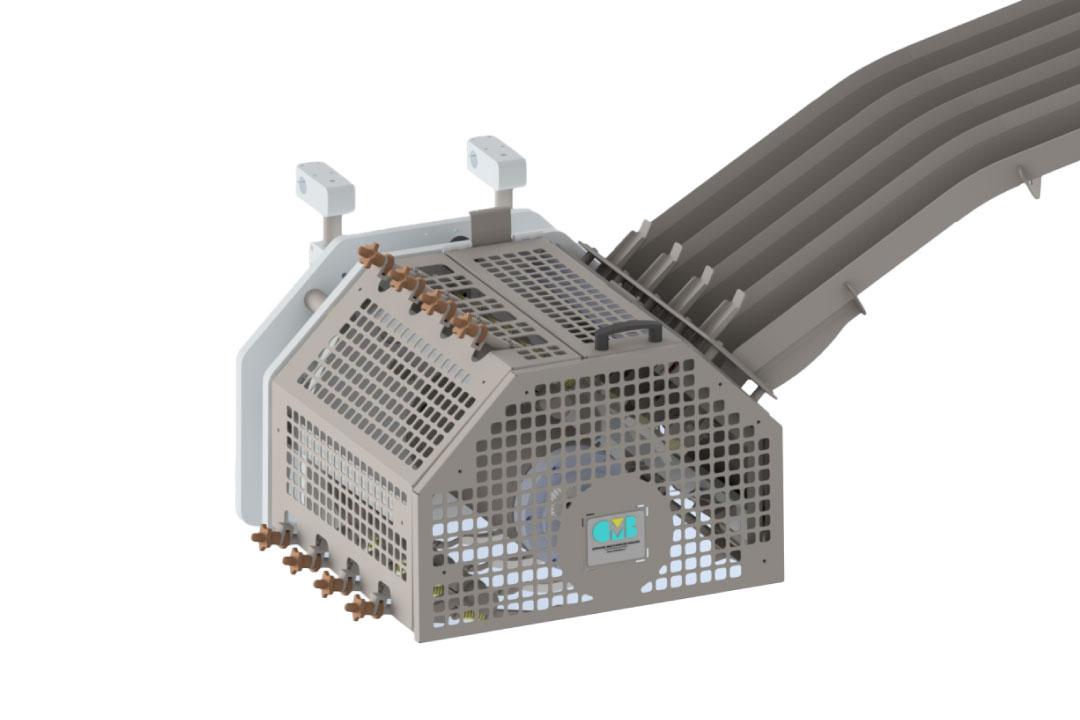

Our biscuit dispenser is the result of years of experience in production lines, and it is no coincidence that it is considered one of the best of its kind by leading companies in the ice cream industry.

After years of testing, we have managed to patent all the strengths of our equipment that set it apart from those produced by our competitors.

The equipment complies with the highest safety standards, both in terms of health regulations and operator safety. It is made from AISI 316L stainless steel and Anodized Anticorodal alloy to ensure durability over time, with components in POM.

The biscuit dispenser operates thanks to a servo-motor installed within the main body, which, through a gear transmission system, transfers the motion to the rotating system.

We have made the equipment versatile for all types of biscuits, thanks to the speed and ease with which format changes can be made.

-

- Equipped with a servo motor.

- Component interchangeability.

- Placement speed >> 100 units/min.

- High accuracy in positioning.

- Scrap percentages << 1%.

- Pneumatic up/down system (automatically reset if interfaced with PLC).

- Interoperability with all production systems.

- Integration capability with the main machine control system.

- The manufacturing process is entirely carried out in compliance with ISO 9001:2015. Component traceability.

- Parts in contact with the product: AISI 316L stainless steel, POM

- External structure in anodized Anticorodal alloy Other parts in stainless steel

- AISI 304 stainless steel. POM plastic parts

- Internal Ra ≤ 1.2 µm

- External Scotch-brite satin finish

- Available formats: upon request

- Customizable equipment construction for each machine.

- Homing sensor (for detection and positioning of the equipment in phase).

- Loading platforms.

- Biscuit box feeding conveyor.

- Installation and training.