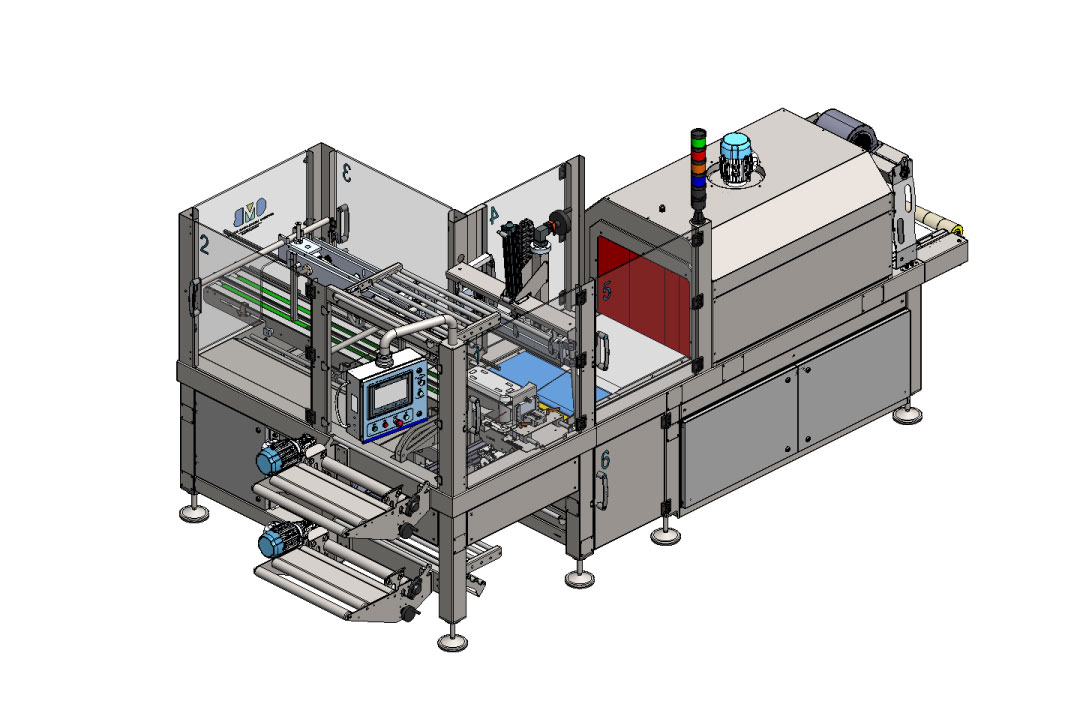

The Shrink Wrapping Bundling System is designed to ensure efficient and secure packaging of products in various formats, wrapping them with shrink film and applying heat to achieve stable and durable packaging. This system optimizes the packaging process by reducing material waste and ensuring maximum product protection.

Thanks to its advanced technology, the system is capable of handling various types of products and bundle configurations, ensuring high productivity and high-quality packaging. The system is fully automated and managed via PLC, allowing for precise control of the packaging stages and integration with the rest of the production line.

- Type: Shrink Wrapping Bundling System with Shrink Film

- Compatibility: Suitable for ice cream production lines and other food products

- Efficiency: Fast and secure packaging to reduce production times.

- Precision: Advanced control of film tension and sealing.

- Reliability: Sturdy structure for continuous and secure operation

- Interfacing: Compatible with industrial automation systems and controlled via PLC

- Hygiene and Safety: Made from certified materials for food contact, compliant with food safety standards.

- Structure: AISI 304 Stainless Steel or Anodized Anticorodal Alloy

- Conveyor System: Modular plastic conveyor belt with high resistance material

- Custom Configurations for sizes and types of bundles.

- Integration Capability: Can be integrated with existing automation systems

- Control Sensors: Used to monitor the shrinkage process.

- Installation and Training: Provided for the proper use of the equipment