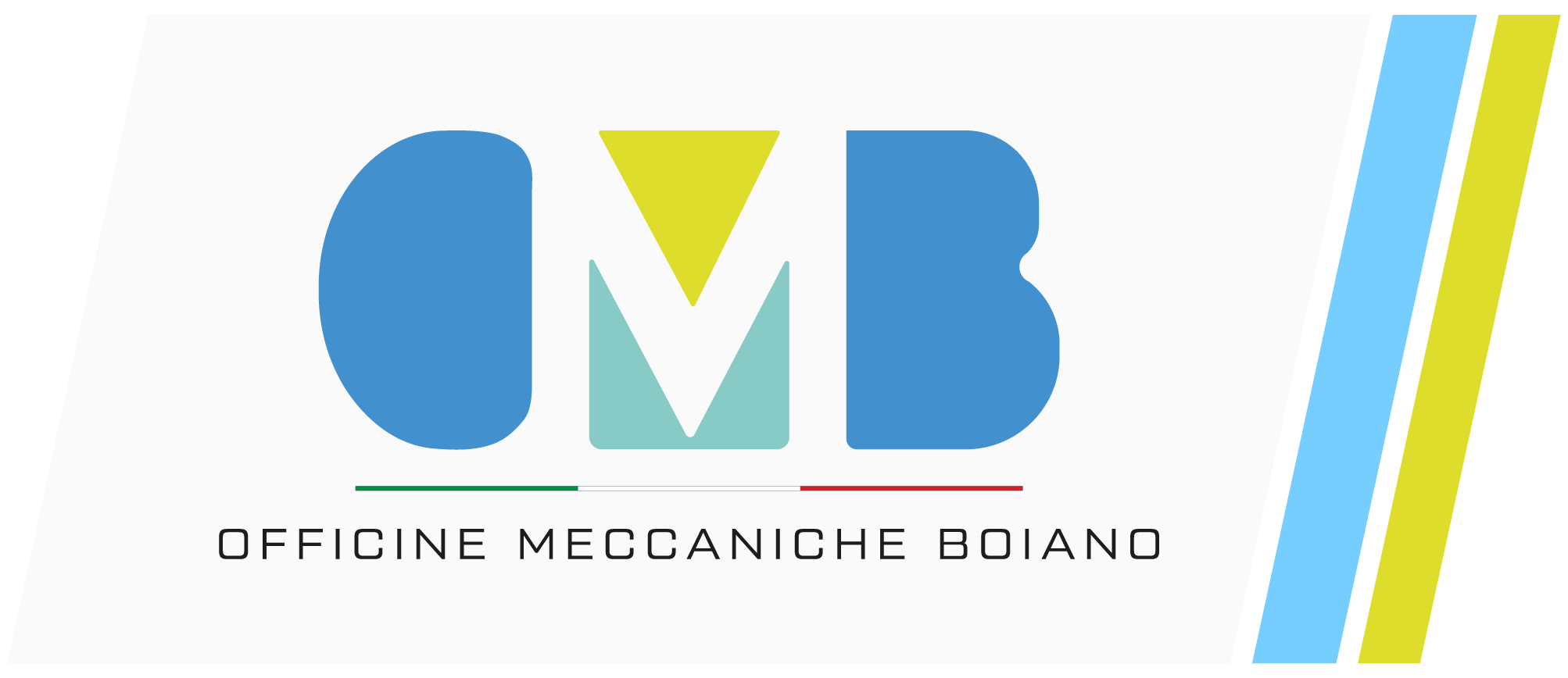

It is equipped with a jacketed tank, which keeps the product at a constant temperature through an optional temperature control system.

The mixing process is facilitated by a motorized agitator controlled via inverter, which can be customized according to the type of inclusions to be mixed, ensuring maximum flexibility, efficiency, and long-term durability.

To simplify handling and mobility, the entire structure is mounted on a frame with four swivel casters with brakes, allowing for easy positioning and stable locking.

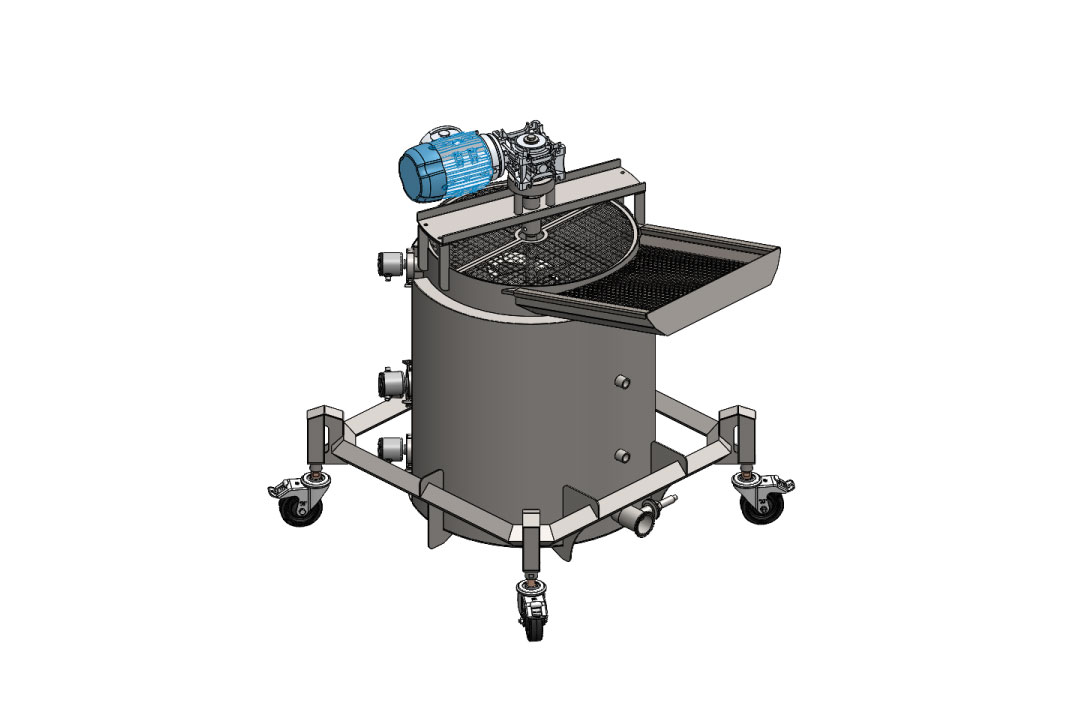

- Fluid flow without obstructions.

- Component interchangeability.

- Integration capability with the main machine control system.

- Available sizes: upon request

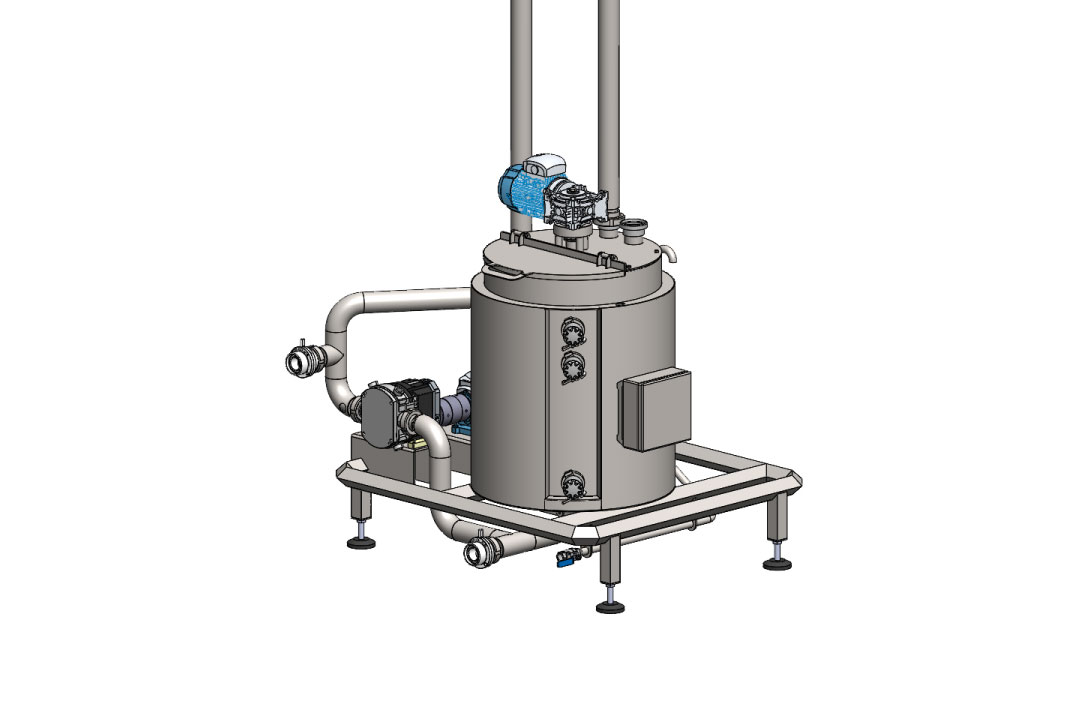

- Product-contact parts

Made with AISI 316L stainless steel for product-contact parts, AISI 304 for other components, and plastic elements in POM and PC - Food-grade bronze parts CuSn6

Surface finish: internal roughness Ra ≤ 1.2 µm; external surface with Scotch-Brite.

- Temperature probe

- Level sensors

- Automated operation when connected to other equipment

- Fully customizable upon request.

- Installation and training.