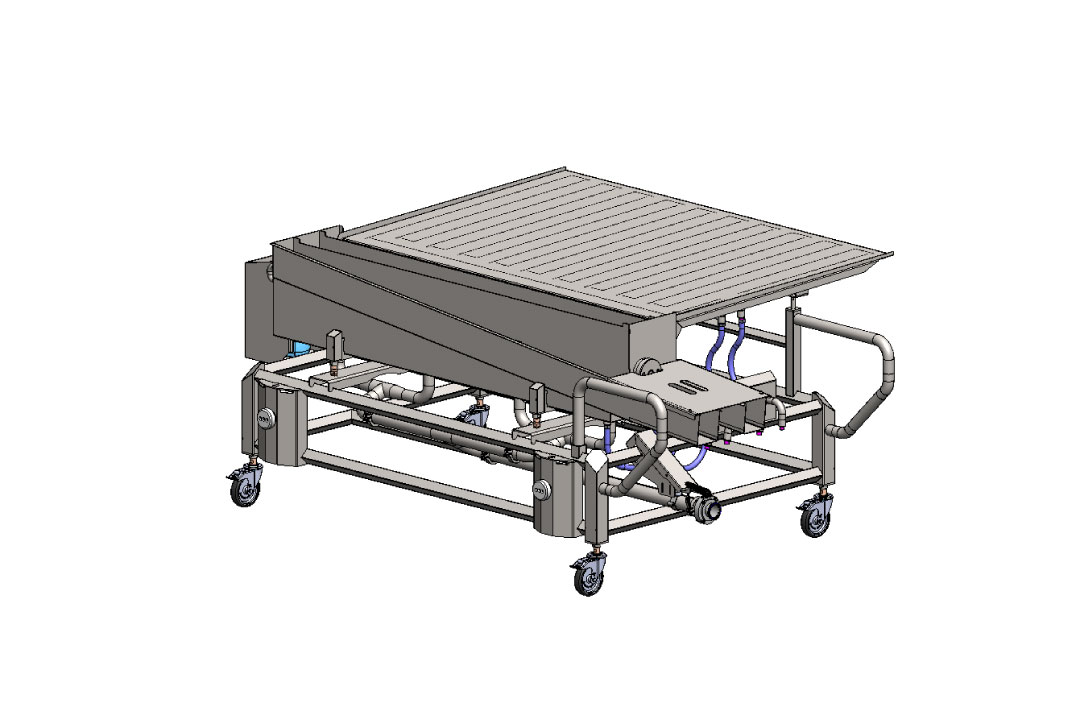

An optional volumetric pump feeds the fluid (chocolate, fruit juice, and others) into the tank, which is equipped with a motorized agitator controlled via an inverter to prevent the sedimentation of inclusions (such as granules, biscuits, and others).

The incoming flow from the pump, once it reaches the limit point, begins to overflow on one or more sides, thus activating a recirculation process if connected to other optional equipment (such as mixing tanks).

The tank is completed with a jacketed reservoir to maintain a constant product temperature, managed by a temperature control system (optional), and equipped with a recovery tray. To simplify management and maneuverability, the entire structure will be mounted on a frame equipped with four swivel wheels with brakes, allowing for easy positioning and stable immobilization.

- Fluid flow without obstructions.

- Component interchangeability.

- Integration capability with the main machine control system.

- Product-contact parts

AISI 316L stainless steel Other stainless steel parts AISI 304 stainless steel - Plastic components made of POM

- Food-grade bronze parts: CuSn6

Surface finish: internal roughness Ra ≤ 1.2 µm; external surface with Scotch-Brite

Available sizes: on request

- Fully customizable upon request.

- Installation and training.