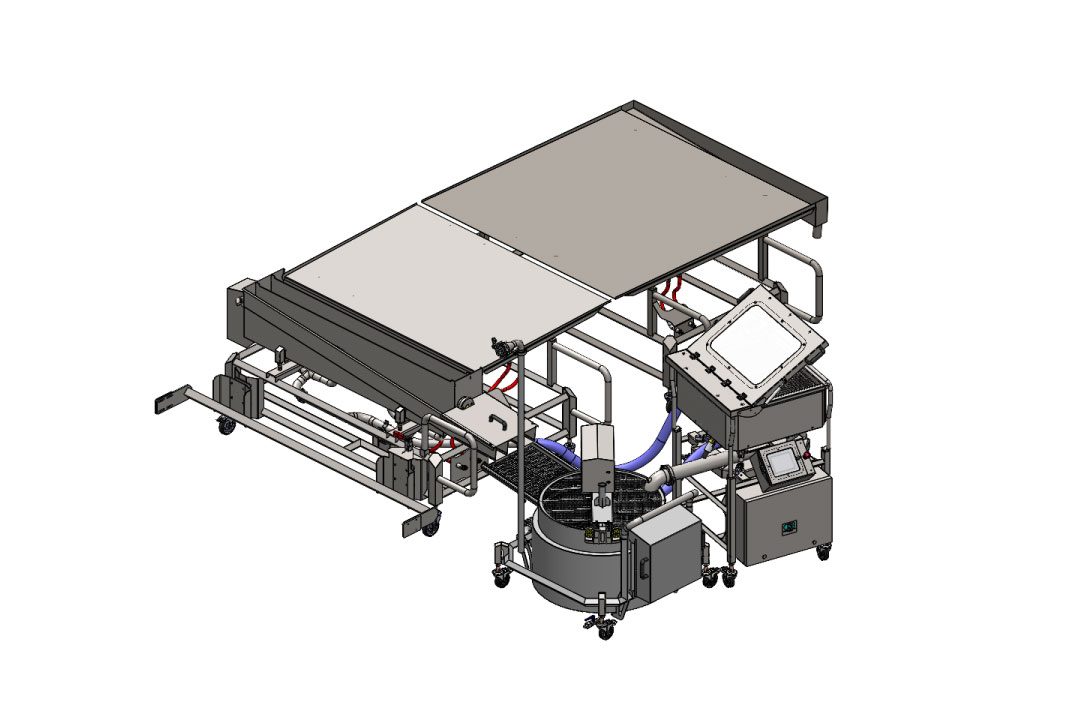

The Dipping System is the ideal solution for achieving near-perfect ice cream coating, capable of handling all types of inclusions. The system is designed to ensure an efficient and uniform process, reducing waste and delivering a high-quality final product.

The system consists of a dosing scale for precise quantity control, a mixing tank to ensure product homogeneity, a dipping tank for uniform coating, a volumetric pump for optimal coating flow, and a secondary chute to reduce waste and facilitate cleaning.

The entire system is heated by advanced temperature controllers, ensuring a stable and optimal temperature throughout the process, preventing unwanted fluctuations that could compromise coating quality.

The entire system is managed by a single PLC with an intuitive, easy-to-use operator panel, allowing recipes to be stored for consistent reproducibility and optimal settings management.

- Type: Automated ice cream coating system

- Main components: Dosing scale, mixing tank, dipping tank, volumetric pump, secondary chute for waste reduction

- Efficiency: Uniform coating with advanced temperature control

- Precision: Accurate dosing thanks to the integrated scale

- Reliability: Stable and high-performing system to ensure consistent quality

- Interconnectivity: Full management via PLC with intuitive operator panel

- Hygiene and Safety: Made from certified materials for food contact, compliant with food safety standards.

- Parts in contact with the product: AISI 316L Stainless Steel

- External Structure: AISI 304 Stainless Steel or Anodized Anticorodal Alloy

- Plastic parts: POM, certified for food use

- Custom configurations available for specific sizes and geometries

- Integration Capability: Can be integrated with existing automation systems

- Control sensors to monitor the dipping process

- Installation and Training: Provided for the proper use of the equipment