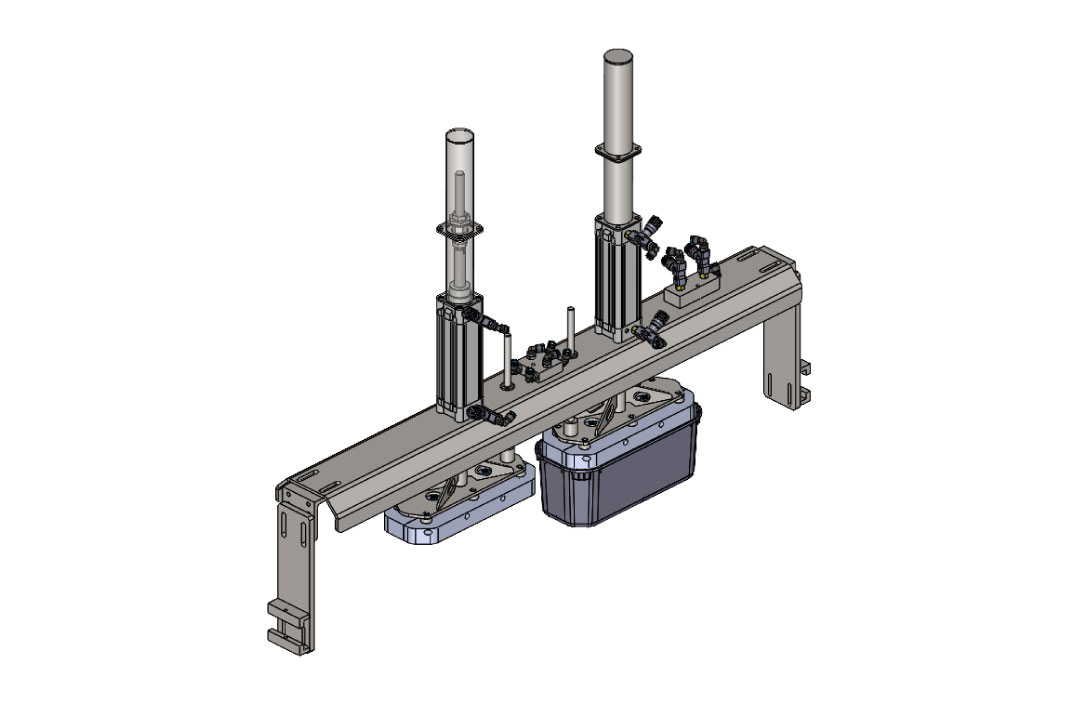

The Sintered Steel Press is designed to ensure uniform pressing of the ice cream inside the tubs, optimizing the compactness and consistency of the product. Thanks to its sintered steel structure, the press guarantees high wear resistance, non-stick properties, and even pressure distribution, preventing deformation of the gelato during the production process.

This advanced technology enhances both the aesthetic and structural quality of the gelato, streamlining the packaging process and ensuring a flawless finished product. The system can be customized to accommodate different tub sizes and shapes, ensuring maximum production flexibility.

- Type: Sintered Steel Press for Ice Cream

- Compatibility: Suitable for ice cream tub production lines

- Efficiency: Uniform pressing to improve the compactness of the ice cream

- Precision: Even distribution of pressure for a uniform result

- Reliability: Sturdy and wear-resistant structure for continuous use

- Interfacing: Compatible with industrial automation systems and controlled via PLC

- Hygiene and Safety: Made from certified materials for food contact, compliant with food safety standards.

- Structure: High-strength sintered steel

- Parts in contact with the product: Non-stick surface for easy removal of the ice cream

- Finish: Specialized treatment to ensure durability and ease of cleaning

- Custom configurations for specific sizes and geometries of tubs

- Integration Capability: Can be integrated with existing automation systems

- Control sensors to monitor the pressing process

- Installation and Training: Provided for the proper use of the equipment