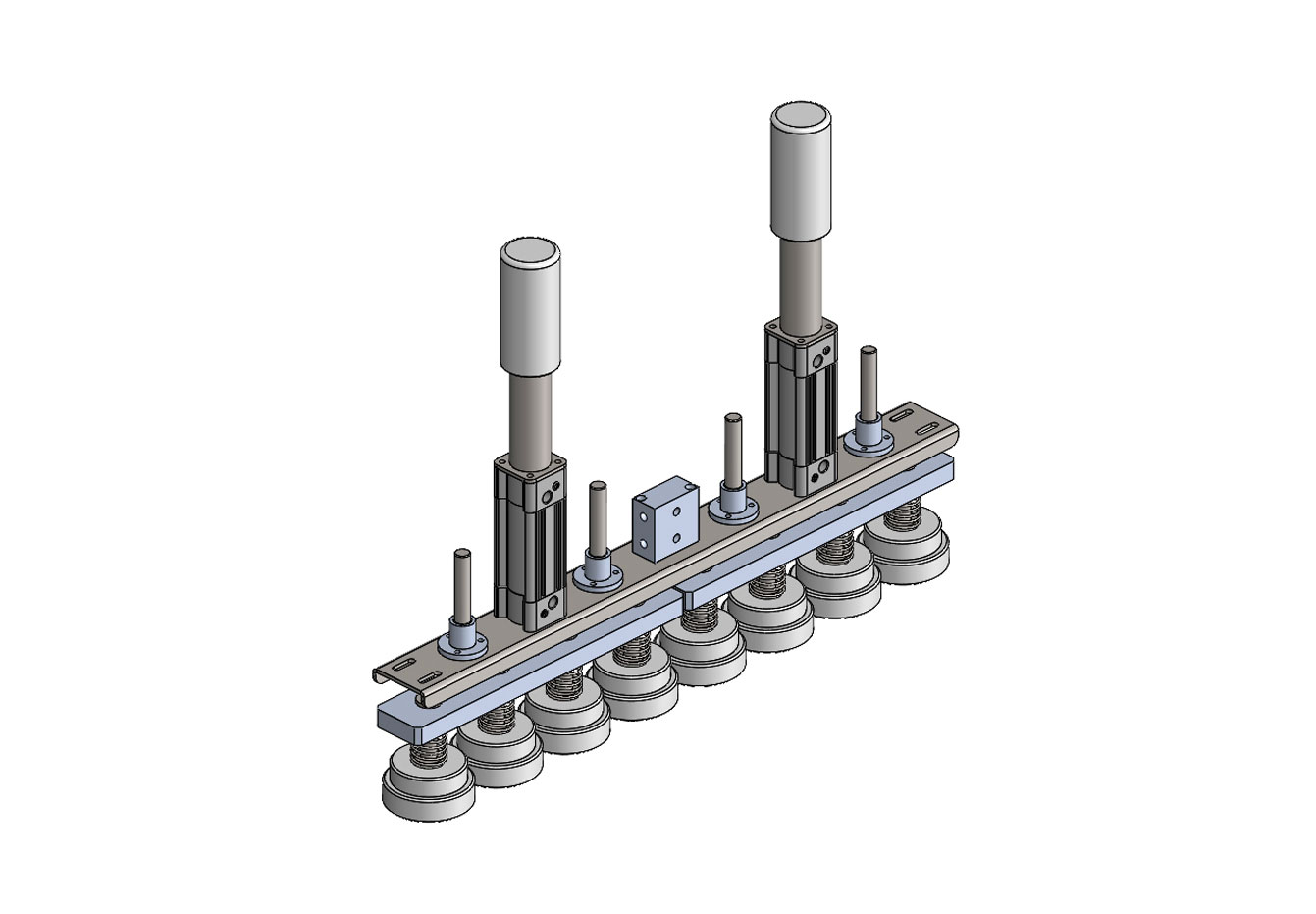

The Pre-Crimping Group is an essential component for cone ice cream production lines, designed to precisely prepare the paper flap on the top lid before the final sealing. Thanks to our advanced technology, the flap is positioned with extreme accuracy, ensuring an optimal and uniform seal.

Reliability and efficiency are the core principles of our Pre-Crimping Group, ensuring that each cone is perfectly prepared for the final sealing stage. This system reduces positioning errors and enhances the overall product quality, optimizing the production process.

- Type: Paper flap pre-positioning system on the lid

- Compatibility: Suitable for ice cream cone production lines

- Efficiency: Precise positioning to ensure uniform crimping

- Precision: Advanced technology for optimal sealing preparation

- Reliability: Stable and high-performance mechanism to ensure consistent quality over time

- Interconnectivity: Compatible with industrial automation systems and PLC control

- Hygiene and safety: Made with certified food-contact materials, compliant with food safety standards

- Parts in contact with the product: AISI 316L Stainless Steel

- External Structure: AISI 304 Stainless Steel or Anodized Anticorodal Alloy

- Plastic parts: POM, certified for food use

- Custom configurations available for specific sizes and geometries

- Integration Capability: Can be integrated with existing automation systems

- Installation and Training: Provided for the proper use of the equipment