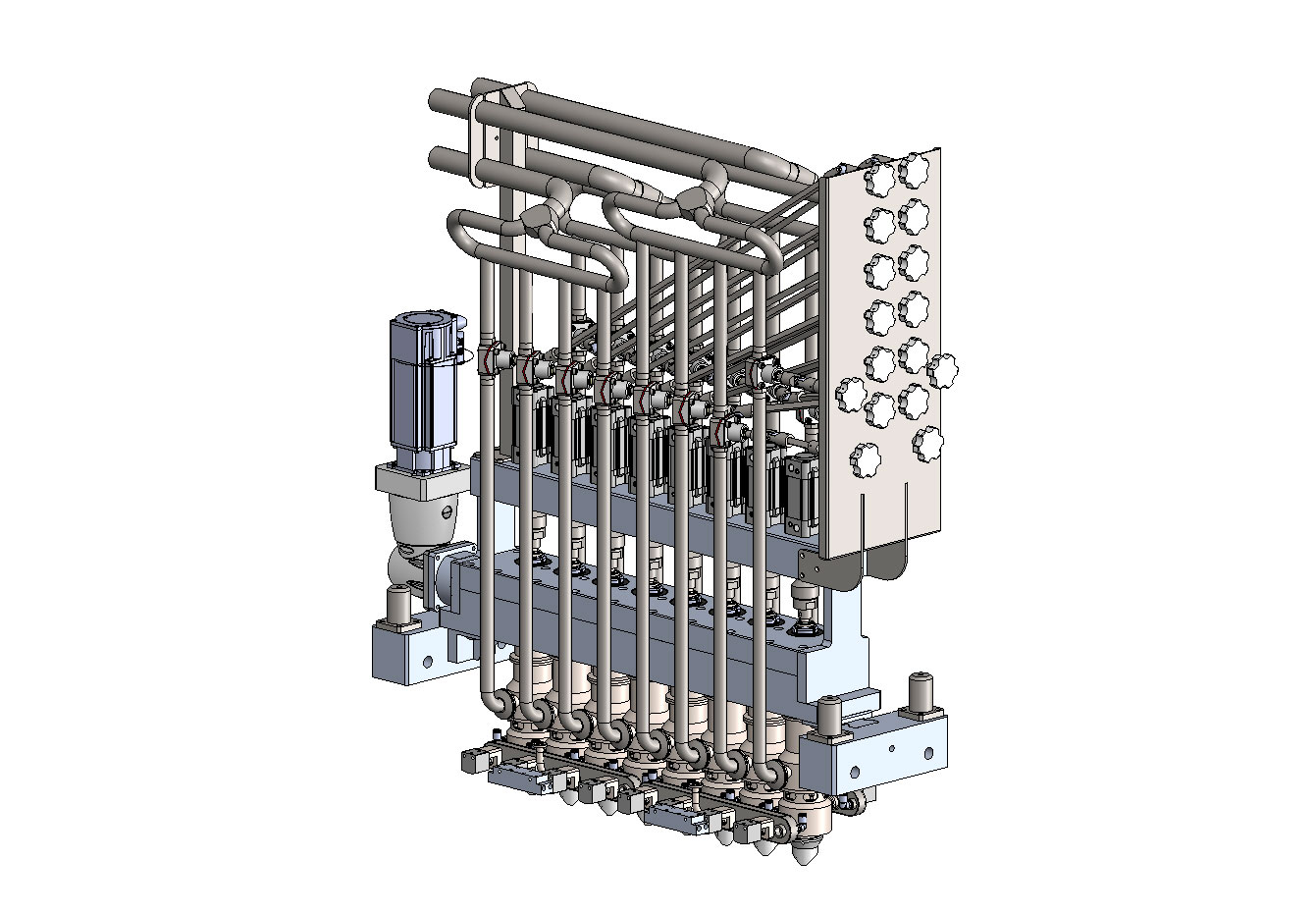

Our timed or volumetric dosing valves are designed to ensure precise and efficient dosing on filling machines and extrusion lines for single-flavor, double-flavor, and triple-flavor products. Thanks to our experience in the industry, we offer cutting-edge solutions for the dosing of food products with high reliability and precision.

The system is designed to seamlessly integrate with rotary dosing units, allowing for the injection of both internal and external toppings, with the ability to include ingredients of various sizes, while maintaining a uniform and controlled dosage. Additionally, we offer customization options for specific geometries and sizes, including complex configurations, to meet every production requirement.

- Type: Timed or volumetric dosing valves

- Compatibility: Suitable for filling machines and extrusion lines for single-flavor, double-flavor, and triple-flavor products

- Dosing system: Internal and external injection of toppings

- Inclusion management: Dosing capability with inclusions of various sizes

- Precision: High accuracy in product dosing

- Flexibility: Customizable configuration for different geometries and sizes

- Interconnectivity: Compatible with industrial automation systems and PLC control

- Hygiene and safety: Made with materials suitable for food contact

- Parts in contact with the product: AISI 316L Stainless Steel

- External Structure: AISI 304 Stainless Steel or Anodized Anticorodal Alloy

- Plastic parts: POM, certified for food use

- Custom configurations available for specific sizes and geometries

- Integration Capability: Can be integrated with existing automation systems

- Position sensors for advanced dosage control

- Installation and Training: Provided for the proper use of the equipment